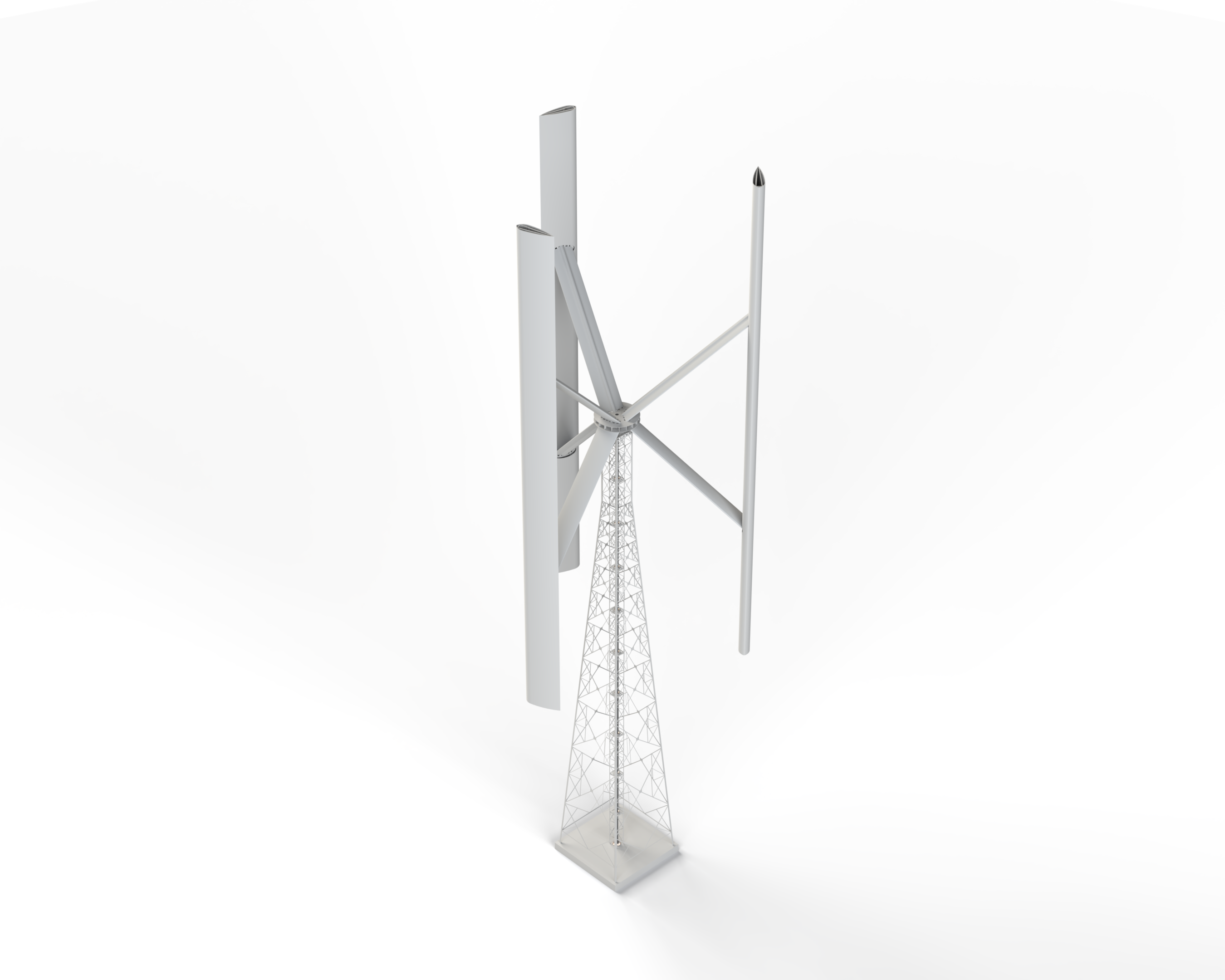

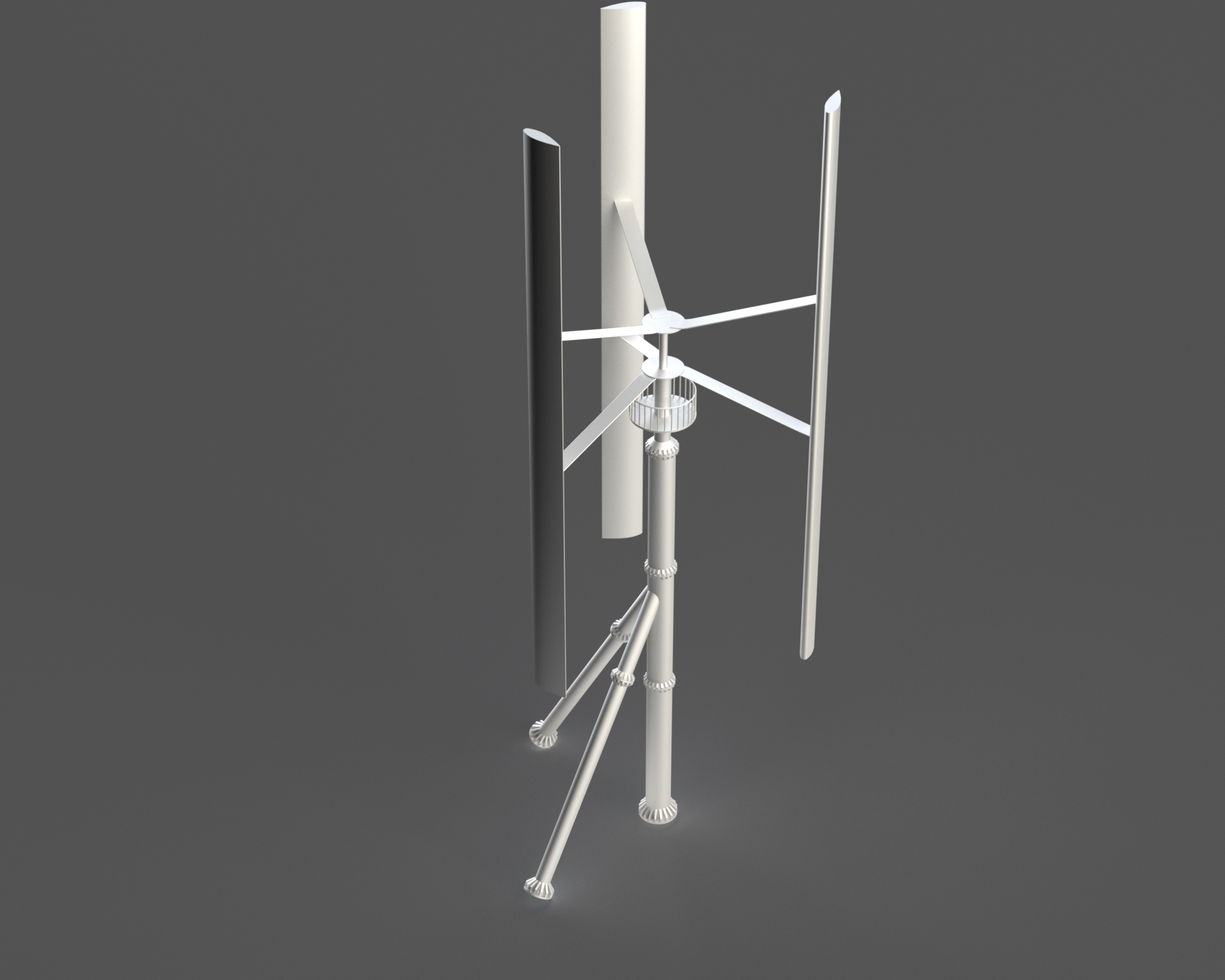

A vertical axis windmill designed for a renewable energy client in India, using L-section structural materials for cost-effective fabrication. The blades and struts were engineered to withstand wind forces and vibrations while ensuring durability.

This Structural Vertical (axis) Windmill was developed for a renewable energy client in India with a brief to use L-section structural material for both cost efficiency and structural simplicity. The design targeted urban and rural microgeneration contexts where modest power output, robustness and low maintenance are priorities.

Structural analysis and modal testing requirements drove the selection of L-section members for blades and struts to simplify fabrication and ensure predictable load paths. Blade geometry was optimized for low-speed wind regimes common in the target sites, and finite element analysis was used to verify stress distribution, deflection and vibrational modes. Connection details were designed to minimize fatigue concentrations and enable easy replacement of blade segments. Prototyping validated aerodynamic behaviour and informed small adjustments to pitch and clearances.

The final design offered an affordable, maintainable windmill that met client performance targets while minimizing material and manufacturing costs. Structural simplicity allowed local fabrication, creating an opportunity for lower supply chain costs and faster deployment in regional projects.